When Disc Brakes Are Released The Pistons Are Retracted By?

In this article I will demonstrate When Disc Brakes Are Released The Pistons Are Retracted By? By which forces? Due to their rapid and nearly loss-free power delivery from the lever blade to the brake caliper, hydraulic disc brakes have long dominated the bicycle brake industry.

The hydraulic transmission ratio allows for high pressure and strong braking performance with a minimum amount of physical force. This safe performance has become crucial for today’s e-bikes and MTBs!

When Disc Brakes Are Released The Pistons Are Retracted By?

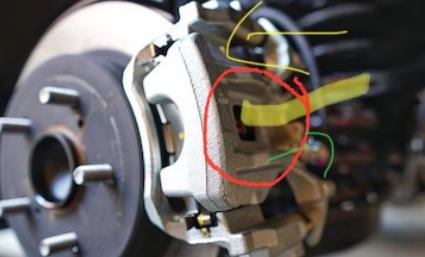

An elastic sealing ring that acts like a spring retracts the piston when the brake is released. Disc brakes are particularly thermally robust and have efficient cooling.

They respond consistently and are mainly unaffected by changes in the brake pad’s coefficient of friction.

Principle Of A Hydraulic Disc Brake

The diameter of the master piston in the brake master is less than that of the pistons in the brake calipers, as seen in the cross-section of a MAGURA MT.

The force at the slave piston—the force with which the brake pads push against the disc—is significantly higher than the force at the master piston—which is produced by the lever blade—because of the ratio of the piston surfaces.

The lever blade offers a mechanical transmission ratio in addition to the hydraulic transmission ratio, multiplying the applied manual force by the law of leverage.

The length and kind of lever blade used can greatly impact the brakes’ modulation and force. This is one of the reasons MAGURA provides a variety of lever shapes for customized brake adjustment.

However, a brake’s overall transmission ratio cannot be adjusted at will. On the one hand, the braking force and gearbox ratio impact the pressure point sensation.

With varied lever blade lengths, the travel of the lever also varies. Using the hydraulic and mechanical transmission ratio as efficiently as possible is the art of a perfect brake; doing so will guarantee flawless braking performance.

Resetting Pads And Compensating For Wear

To confirm that the rotor can rotate freely once the brake is applied and not permanently stopped by the piston and brake pad, the piston is retracted inside the brake caliper by quad rings.

These quad rings deform with each slave piston movement in a predetermined groove, which controls how far the pistons retract.

When the brake pressure is released, the quad ring returns to its initial position and shape, retracting the piston. The master piston is simultaneously pressed back by a spring.

The slave piston of the brake caliper must travel closer to the rotor when a brake pad wears to make up for the wear. To accomplish this movement, the piston may move on the sealing ring.

The amount of oil in the system is adjusted simultaneously by oil flowing in from the expansion reservoir through the so-called sniffer hole.

There is no pressure buildup in the expansion reservoir during braking because this oil flow is already possible while the master piston is moving back.

The bleed screw on the expansion reservoir merely serves as a sealant during the braking operation and is not subject to pressure.

The oil, which expands as the system heats up, also has additional room thanks to the expansion reservoir. In extreme circumstances, the brake could lock without this correction.

The Brake Pad Is More Than Just A Worn Part

It is common to undervalue brake pads’ role in brake performance. Selecting the best pad may reduce noise and enhance braking power by more than 20%. The rotor’s diameter and other factors are the same.

For the same manual effort, a 203 mm rotor generates 10% more than a 180 mm rotor, while a 220 mm rotor generates 10% more.

It’s only sometimes best to use a bigger rotor. Total weight and usage scenario are the two key variables in this situation.

Conclusion

When disc brakes are released the pistons are retracted by mechanical and hydraulic forces. By ensuring that the brake pads disengage from the brake rotor during this vital operation, the wheel is free to rotate without coming into touch with any friction.

When the brake lever is released in a standard hydraulic disc brake system, the hydraulic pressure inside the brake lines is released, which reverses the hydraulic force operating on the pistons.

This retraction is necessary to prevent the brake pads and rotors from wearing down too quickly, ensure the braking system operates smoothly, allow for controlled acceleration and deceleration, and ensure vehicle safety.

Frequently Asked Questions

How do disc brake pistons retract?

Due to decreased braking fluid pressure and the piston seals returning to their uncompressed state, when you depress the brake pedal with your foot, the pistons—and subsequently the brake pads—retract. Both fixed and floating brake calipers contain pistons.

What retracts the pistons in a disc brake caliper?

The caliper piston’s ability to retract back into its housing is made possible by the square-cut seal. The square-cut seal may not function even though you can physically push the piston in.

What happens inside a disc brake when brakes are released?

The brakes release, and the braking fluid returns to the master cylinder when you let go of the brake pedal. If the wheel has a disc brake, the braking fluid will cause a piston to move, slowing the vehicle down by pressing brake pads against a disc or rotor, which is a part of the wheel.

Why won’t my disc brake pistons retract?

A damaged piston surface that travels back and forth on the seal is frequently to blame when brake pistons fail to retract into the caliper. Additionally, if things get really bad, one or both pistons can cease moving.

Welcome to the exhilarating world of Matt Rex, a professional car racer turned renowned vehicle enthusiast. Immerse yourself in his captivating blog as he shares heart-pounding adventures, expert reviews, and valuable insights on cars, trucks, jets, and more. Fuel your passion for speed and discover the beauty of vehicles through Matt’s engaging stories and meticulous expertise. Join the ever-growing community of enthusiasts who find inspiration and expert advice in Matt Rex’s blog—a digital hub where the thrill of speed meets the pursuit of knowledge.

![Car Revving Engine Noise Complaint [Causes + Fix]](https://www.turbochaos.com/wp-content/uploads/2023/11/Car-Revving-Engine-Noise-Complaint-768x623.jpg)